product introduction

Quiksep AF automatic ultrafiltration system adopts imported pump head, valve, sensor and other devices, as well as advanced control concept and GMP compliant control software. It can automatically test water flux and reserve integrity test port, which can meet the increasing demand of diversity in biotechnology and biological process.

Quiksep AF can be used for concentration, filtration (desalination and buffer replacement) and size separation of biomolecules. In addition, it can also be used for the removal and clarification of cells and cell fragments in fermentation liquid or cell culture liquid.

Design and specification index allocation basis

A) molecular weight and retention requirements of target products

B) concentration multiple requirements, dialysis volume and determination of dialysis end point

C) product activity and recovery requirements

D) batch and process time

E) chemical compatibility of all components in solution

F) operation conditions such as flow and pressure of ultrafiltration process

G) cleaning effect test, water flux measurement, integrity judgment

Meet the demand

A) design meeting cGMP concept requirements;

B) materials complying with FDA requirements;

C) self draining and online cleaning (CIP);

D) the system is easy to operate and friendly all Chinese operation interface;

E) all sanitary structural designs.

Product characteristics

1) the standard ultrafiltration membrane clamp can adapt to the famous brands such as Merck and sartorius;

2) equipped with flow, temperature and other sensors, which can calculate the flux and concentration factor online;

3) equipped with pressure sensor to detect the pressure at each port, and automatically calculate the transmembrane pressure TMP, transmembrane pressure difference △ p;

4) equipped with precision proportional valve, it can accurately control the opening of the return end and realize the precise control of TMP;

5) according to the set flow, the system can automatically control the tangential flow by adjusting the speed of the rotor pump in real time;

6) the flow, temperature, conductivity, pH, UV and other online detectors can be flexibly configured in the system according to the process requirements to record the operation curve in real time;

7) the independently developed control software conforms to GMP specifications, and the data and log are recorded in real time, traceable and non modifiable.

System component diagram

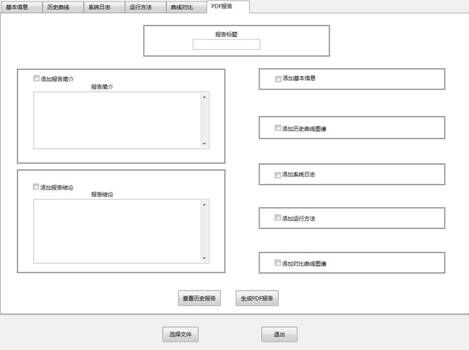

五、Schematic diagram of software operation interface

Concise and powerful method editing and automatic control function. Automatic collection can be realized according to UV, conductivity, etc.; users can easily program.

Stable and reliable data acquisition and management functions. ATFF collects process data and records logs in real time. Even after power failure, data will not be lost, and all data will be saved to the same file for easy migration and backup. Data view is also very convenient, curve, log, operation information and so on are clear at a glance.

Pdf report can be generated directly, curve comparison of different batches in history, etc.

Main devices

1) liquid supply pump

Johnson MP series sanitary rotor pump, pump head liquid surface are 316L stainless steel, internal surface electropolishing. The pump adopts SiC / SiC composite single mechanical seal and the driving motor is 380V 50Hz.

2)

Membrane fixture

The membrane clamp is made of 316L stainless steel, and the structure of the clamp takes into account the minimum residual and sanitary requirements.

3)Pressure sensor

The digital pressure sensor is respectively installed on the feed pipe and return pipe of the ultrafiltration device, and the contact film of the pressure sensor is made of 316L stainless steel. When the working pressure reaches the set pressure value, the high and low pressure alarm signals can be given and the liquid supply pump can be stopped. When the pressure is high, the membrane package can be protected from damage, and the idling of the pump when there is no material can be avoided.

A biological products enterprise (fat) in Shandong Province

A biological product enterprise in Jiangsu Province