1. Overall design of quiksep AC automatic chromatography column

Quiksep AC fully automatic chromatography column can provide axial precise lifting and positioning, also can control the torque to meet different user's column loading requirements under the condition of ensuring the column loading pressure; it can also realize automatic filling of packing, automatic recovery of packing, cleaning of column tube, moving of separation column tube, dismantling of stainless steel screen through two pneumatic diaphragm pumps and unique structure on the workstation. Because the loading and unloading guide of the workstation is easy to understand, it can significantly improve the working efficiency and shorten the operation time, and the fixed program can ensure the best performance of the column efficiency and the repeatability of the loading effect.

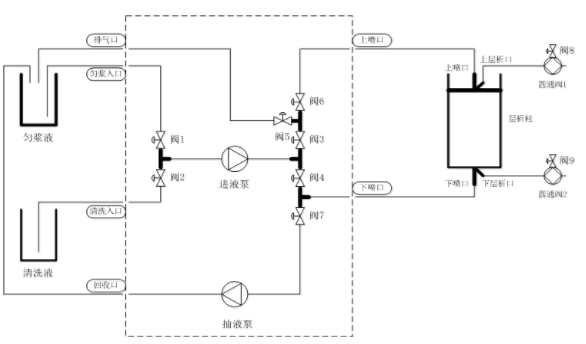

Quiksep AC automatic chromatography column can be installed in the way of pump or suction. By using the way of pump glue, the maximum filling height can be realized, and the utilization rate of the equipment can be significantly improved; if the way of column head sealing glue suction is adopted, the same column effect result can be guaranteed, the operation is convenient, and the performance is stable.

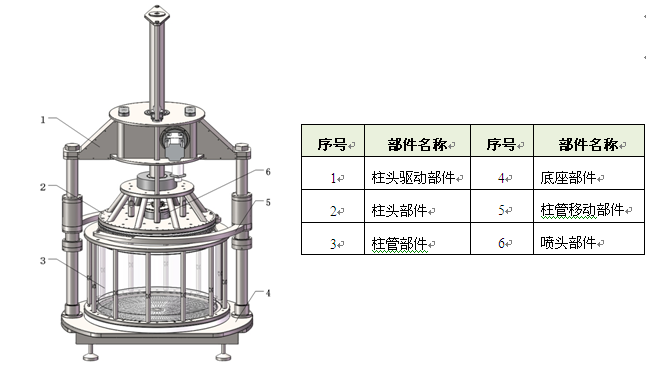

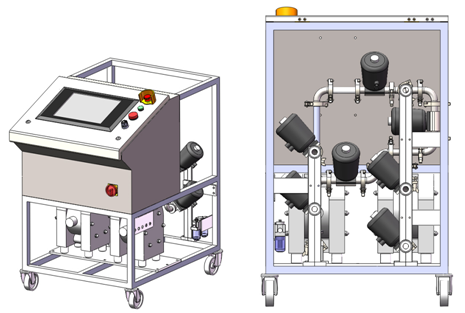

Quiksep AC automatic chromatography column is mainly composed of six parts, and the schematic diagram of its components is shown in the following figure:

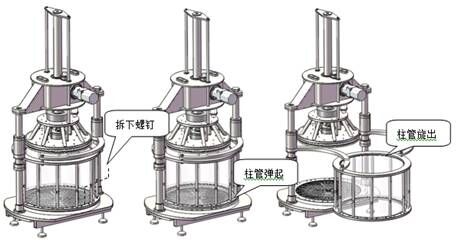

When removing the column and cleaning the column and screen, the process is as follows:

In a word, this design makes the standardized production faster, the series specification combination easier, and also makes the user's operation more convenient, fast and safe.

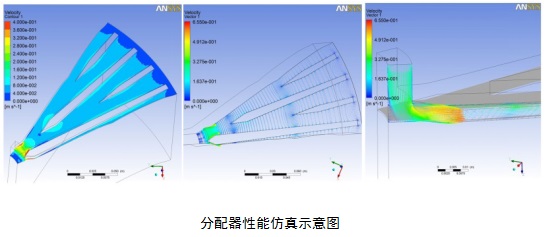

2. Mechanical design of distributor according to advanced concept

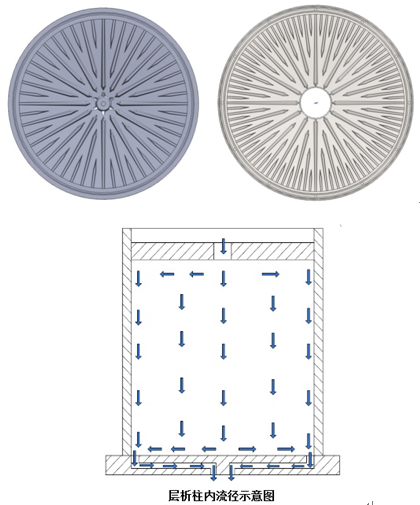

Fluid dynamic simulation, optimization design, reliability design, virtual design, three-dimensional modeling, and product life cycle design make the product performance have a single central nozzle and a guide runner. The nozzle for direct injection prevention is made together with the guide groove, which is positioned at the center of each unit to prevent the ejected liquid from directly entering the column without passing through the distributor. The patented distributor design ensures that all flow paths are of the same length, thus more effectively ensuring the distribution effect.

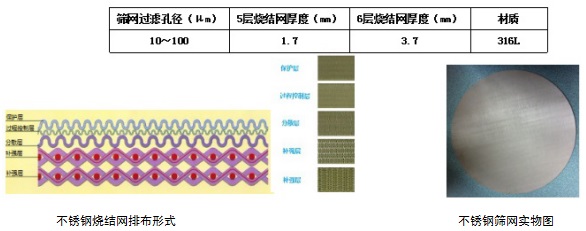

3. The upper and lower screens are stainless steel sintered screens with multi-layer structure.

The upper and lower screens are stainless steel sintered screens with multi-layer structure. Different from polyethylene screen: Polyethylene screen is hydrophobic and needs to be fully wetted before column loading, while stainless steel screen does not need to be wetted in advance. The stainless steel sintering mesh is composed of protective layer, process control layer, dispersive layer and 2-3 reinforcing layers.

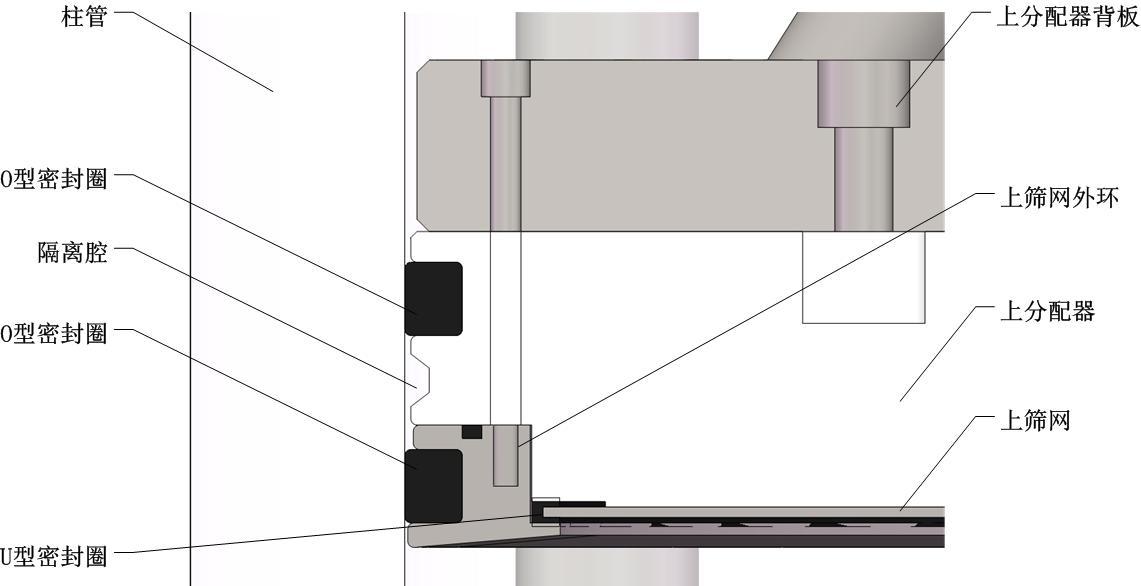

4. The sealing structure of chromatographic column mainly considers the reliability of sealing, the maximization of effective area and the minimization of dead volume.

The sealing form of the column head is shown in the figure below. The double-layer O-ring is used to seal between the column pipe and the moving column head, which plays the role of double sealing.

The screen is sealed with U-ring. The inner surface of the U-ring can wrap the upper and lower surfaces and sides of the screen, effectively preventing the leakage of glue, and the volume of the U-ring is very small, which can effectively prevent the screen from deformation.

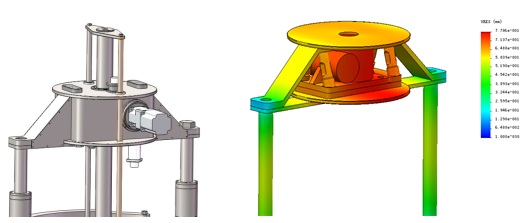

5. Reliable structural design

Due to the emergence of a large number of fillers with high hardness and small particle size, the pressure resistance of the original chromatographic column is obviously insufficient. Therefore, in order to meet the demand of quiksep AC series automatic chromatographic column, 5bar is used as the standard operating pressure, so higher requirements are put forward for the structural strength.

Through a large number of simulation calculation, we get a reliable beam structure design, to ensure that when the pressure of equipment is 5 bar, the deformation of the column head does not exceed 2 mm.

6. Column loader as an independent operating system,

It is composed of PC, PLC, solenoid valve, pneumatic diaphragm pump, pneumatic diaphragm valve, gas triplet, flow regulating valve, etc.

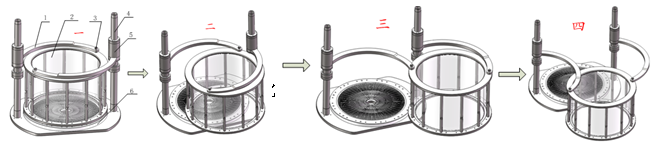

The software of automatic chromatography is divided into manual mode and automatic mode. The manual mode can manually control the rising or falling distance and speed of the column head, and monitor the current position of the column head in real time. The automatic mode is mainly divided into four modules: packing column, unloading column cleaning, disassembling column pipe and assembling column pipe. According to the guide, the chromatographic column can be disassembled and cleaned conveniently and quickly.

河北省某生物制品企业

A pharmaceutical enterprise in Xiamen

A vaccine manufacturer in Gansu Province